Decentralized Wastewater Treatment Technologies

Modified Septic tank is a simple low-cost system. The system was based on modification of conventional septic tank by including an integrated aerated-settling chamber. Two modules of bacterial growth (suspended and attached) are tested for the purpose of treating treat domestic wastewater. Two septic tanks with dual operational conditions (anaerobic and aerobic) are constructed and operated in parallel. Unlike the suspended growth reactor, the anaerobic/aerobic fixed bed reactor contains corrugated plastic sheets, where the microorganisms are attached to the surface of the packing material.

Sequencing Batch Reactor (SBR) is a discontinuously operated fill- and draw activated sludge process. It is uniquely suited for wastewater treatment applications characterized by low or intermittent flow conditions. Three systems have been installed at Fuheis demonstration site conventional SBR plant, an SBR with ultra violet (UV) light and a newly invented Continuous Batch Reactor (CBR). ATB Environmental technology ltd. supplied the three systems.

The SBR system at Fuhais consists of two compartments. The first one receives raw wastewater from the inlet tank and used as a preliminary treatment unit. The second compartment receives the preliminary treated wastewater and is considered as a secondary treatment unit, in which all treatment processes occur. The device consists of clear water pump, aerator and de-sludging pump. All the reactors are operated in the mode with feed, anaerobic, aerobic, settling and decanting phases and therefore all biological, oxidation, sedimentation, nitrification and de-nitrification processes occur in a single tank.

A newly invented device at ATB Company has also been installed at the demonstration and test site at Fuheis. Continuous Batch Reactor designed to reduce the electrical consumption and O&M work. Tow settling tanks designed in away to separate the suspended solids from the treated water. Aeration, de-sludging and feeding are done by a small compressor. Unlike the SBR system, the water leaves the biological chamber through the settling tanks by gravity to the irrigation tank. The CBR system can be adapted to decentralized application for small units.

Two Eco-systems-constructed wetlands- have been constructed at the site.

The Multi-stage Single-pass Vertical Filter system was designed to produce high quality effluent in a passive way (no electricity or pumps required on a sloping site). It is designed to treat 3.4m3/day (approx. 40 people). The system consists of a septic tank (primary treatment), 1st stage Vertical Filter (secondary treatment and nitrification), Organic Denitrification Reactor (removal of nitrate), and a 2nd stage Vertical Filter (pathogen reduction and further polishing). The vertical filters will be tested with and without wetland plants to see the effect on the performance and

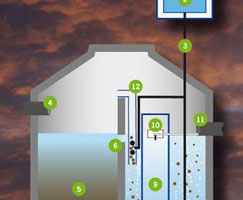

The Recirculating Vertical Filter System is a state-of-the art eco-technology designed to produce a high quality effluent within a relatively small foot-print. It consists of a septic tank for primary treatment, followed by a recirculation tank. Effluent is pumped from the recirculation tank onto the vertical filter before then flowing through a flow splitting device from where am portion of the effluent is returned to the recirculation tank while the rest leaves the system and is used for irrigation. The system is designed to treat 2 m³/day (approx. 25 people).

Membrane Bio-reactor is an intricate technology that entails state of art tools of separation. MBR produces high quality effluent that can be used for a wide variety of reuse applications complying with the strictest guidelines. MBR unit is constructed to demonstrate its application as a viable option for decentralized wastewater treatment. The MBR unit was provided by HUBER SE as containerized system. The key element in the whole treatment process is the ultra filtration membranes with a pore size of 38 nanometers.

Sewage sludge requires transport, disposal or further processing, which is becoming an increasing problem in Jordan. Eco-technological sludge treatment performs with the volume reduction and mineralization of municipal sewage sludge without an additional energy input. Sludge Dewatering Reed Beds (SDRB) have been introduced as a new method of sludge treatment in Jordan. At the Demonstration site, two planted (common reed; Phragmites Australis) and 1 unplanted sludge drying bed has been constructed. Anaerobic treatment aims at stabilization of municipal sewage sludge and produce high quality compost residues.

Anaerobic treatment aims at stabilization of municipal sewage sludge and production of high quality fermentation residues. The production of biogas contributes to the competitiveness of the technology. In addition to that, the anaerobic treatment leads to a significant reduction of pathogenic organisms. The company HUBER SE supplied a containerized plant which consists of a mechanical solid/liquid separator (pipe strainer), followed by a hydrolysis reactor and an anaerobic bioreactor.